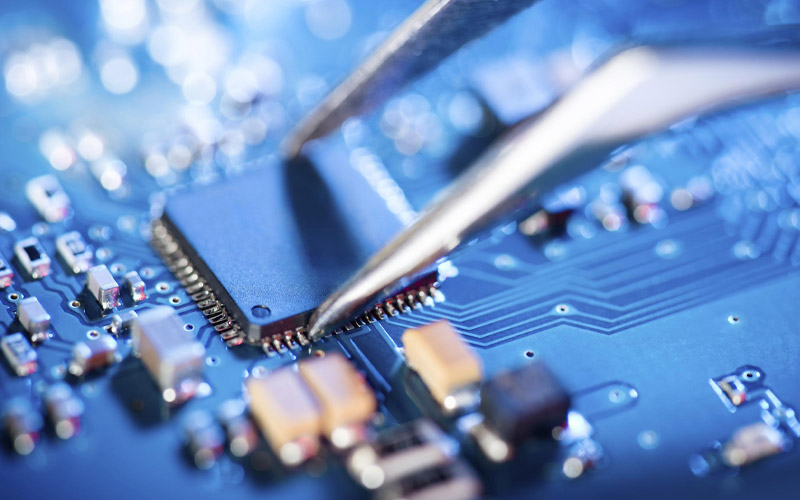

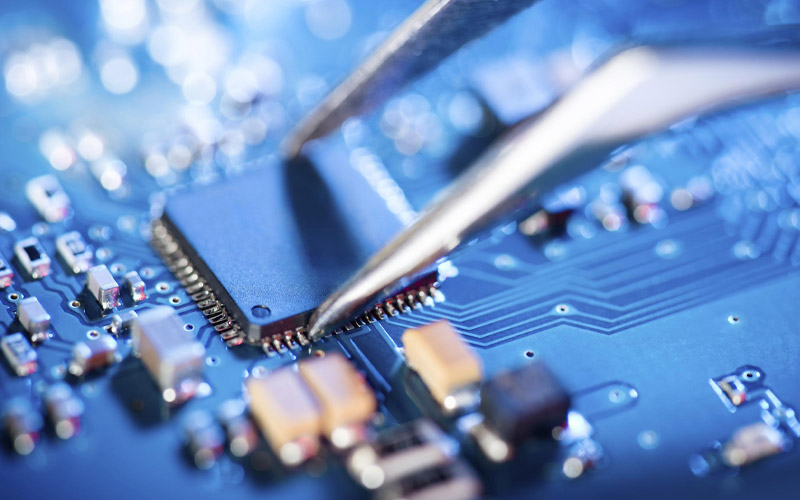

When soldering IC chips, attention should be paid to the following issues to ensure the quality of soldering and the normal operation of the circuit board:1. Clean environment: Before welding, ensure that the surrounding environment is clean and free of dust. Dust may not only affect the firmness of welding, but also carry static electricity, causing damage to circuit boards.2. Tool preparation: Prepare the necessary welding tools in advance, such as an electric soldering iron, and ensure accurate temperature adjustment. The general temperature for chip soldering is around 380 degrees Celsius.3. Directionality: The chip and base have directionality and need to be welded strictly according to the direction of the notches on the PCB board to ensure that the notches on the chip, base, and PCB correspond.4. Solder joint quality: When welding, ensure that there is tin around the solder joint to firmly solder it and prevent false soldering.5. Pin handling: Before installing the chip, it is best to slightly bend the pins on both sides to facilitate insertion into the corresponding socket on the base.6. Heating time: During the welding process, attention should be paid to the heating time to avoid excessive damage to the IC or PCB board. Once signs of solder melting or slight sinking of the IC are detected, heating should be stopped immediately.7. Post welding treatment: After welding is completed, wait for the PCB board to cool down, then use cleaning agent to clean and blow dry the welding points, and check for virtual soldering and short circuits. If there is any virtual soldering or short circuit phenomenon, it should be repaired in a timely manner.8. Safety precautions: When using a soldering iron or hot air gun, pay attention to safety to avoid burns or damage to other components.Following the above steps and precautions can ensure a smooth and reliable soldering process for IC chips, thereby improving the overall performance and stability of the circuit board.

03-21Knowledge

The storage and shelf life of PCB circuit boards are important steps to ensure the quality and performance of the circuit boards. Here are some key information about the storage and shelf life of PCB circuit boards:Storage conditions:1. Temperature and humidity: PCB circuit boards should be stored in an environment with a temperature range of 22 ℃± 4 ℃ and a humidity below 70% RH. For antioxidant boards, the temperature range can be relaxed to 10-28 ℃, but the humidity also needs to be controlled below 70% RH. Meanwhile, the storage location should avoid direct sunlight and preferably be stored in a dry and ventilated warehouse.2. Packaging requirements: Circuit boards should be vacuum packed or other moisture-proof measures should be taken during storage, such as using bubble wrap and moisture-proof beads. Bubble film can wrap around the side of the box, providing good moisture resistance. Meanwhile, packaged products should be classified and labeled for easy management and identification.3. Storage location: PCB circuit boards should be stored in a dry and ventilated place away from the ground, and the box must be separated from the wall to avoid moisture and temperature changes affecting them.Shelf life and precautions:1. Unopened PCB shelf life: Under the above storage conditions, the reference period for antioxidant boards is 6 months, and it is usually recommended to use them within 3 months. The reference period for other surface treatment boards is 12 months, but it is usually recommended to use them within 6 months.2. Shelf life of opened PCB: Under the same storage conditions, it is recommended to complete SMT work within one week after opening the PCB to avoid moisture or oxidation of the circuit board.3. Handling of exceeding the shelf life: If the PCB circuit board exceeds the shelf life, QA review is required. Only qualified products can be shipped, while unqualified products will be scrapped.In addition, there are some specific situations that need to be noted:• In the PCB production process, circuit boards need to be baked at 120 degrees Celsius for at least 4 hours before SMT SMT placement, which is stored in vacuum packaging for more than 3 months.• If the manufacturing date of the PCB board exceeds 2 months but the seal is not opened, it can be directly put online for use; If opened, it must be put online and used up within 5 days, and the date of opening must be indicated. If the deadline is exceeded, it needs to be baked at 120 ± 5 ℃ for a certain period of time before going online.

03-21Knowledge

There are many types of chips, and the following are some common types of chips:1. Microcontroller (MCU): This is a chip that can run programs autonomously.2. Digital Signal Processor (DSP): mainly used for processing and storing digital signals.3. Analog to Digital Converter (ADC): Used to convert analog signals into digital signals.4. Digital to Analog Converter (DAC): Used to convert digital signals into analog signals, allowing digital signals to be read by peripherals.5. Operational amplifier (OPAMP): It can amplify small electrical signals into large electrical signals.6. System on Chip (SoC): It integrates components such as microcontrollers/processors, memory, communication interfaces, and various sensors, and can achieve rich functions through simple programming.In addition, there are several common types of chips:• Memory chip: used to store digital information, including types such as memory, flash memory, EEPROM, etc. Flash memory chip is a type of chip used for data storage in digital products, mainly in two types: NAND and NOR.• DRAM chip: refers to dynamic random access memory, mainly used as internal memory in systems such as computers.• SRAM chip: static random access memory.• EPROM chip: It can program read-only memory and can be erased and reprogrammed through special UV lines.In addition, there are also types such as custom circuits (ASICs) and programmable logic devices (PLDs). Customized circuits are chips customized according to user application requirements, while programmable logic devices include a series of programmable logic chips.The above are just some common types of chips. In fact, with the development of technology, the types and functions of chips are constantly expanding and updating.

03-21Knowledge

The color of a PCB (printed circuit board) does not represent a specific function or performance. The main difference between different colors of PCB boards is the color of the solder mask ink used, and the solder mask layer mainly covers the wires to provide insulation and prevent short circuits. These ink colors include green, blue, red, black, etc.Green solder mask ink is the oldest, cheapest, and most popular in history. The reason why it is widely used is that during the board making process, green has a better visual effect in the yellow light room and also has a better recognition effect on the instrument; Secondly, in processes such as SMT welding, a green background color helps with optical positioning calibration; The third reason is that green causes relatively less damage to the eyes, making it more suitable for workers to work for long hours.The blue and black PCB boards have a certain conductivity due to the addition of cobalt and carbon, so there may be a risk of short circuits. However, if the design and manufacturing process of the PCB are identical, color will not affect the performance and heat dissipation of the PCB.In the eyes of some people, black PCB boards may represent high-end products, but in reality, black PCB boards, due to their surface wiring being almost completely covered, bring great difficulties to later maintenance, and the yield rate is relatively low, so the price will be slightly higher. In recent years, people have gradually started to use solder mask paints such as dark green, dark brown, and dark blue to make manufacturing and maintenance more convenient.Overall, the color of PCB boards is mainly for the convenience of manufacturing, maintenance, and visual recognition, and does not determine their performance or function. When selecting PCB board colors, it is necessary to consider practical application requirements and working environment.

03-21Knowledge

When soldering IC chips, attention should be paid to the following issues to ensure the quality of soldering and the normal operation of the circuit board:1. Clean environment: Before welding, ensure that the surrounding environment is clean and free of dust. Dust may not only affect the firmness of welding, but also carry static electricity, causing damage to circuit boards.2. Tool preparation: Prepare the necessary welding tools in advance, such as an electric soldering iron, and ensure accurate temperature adjustment. The general temperature for chip soldering is around 380 degrees Celsius.3. Directionality: The chip and base have directionality and need to be welded strictly according to the direction of the notches on the PCB board to ensure that the notches on the chip, base, and PCB correspond.4. Solder joint quality: When welding, ensure that there is tin around the solder joint to firmly solder it and prevent false soldering.5. Pin handling: Before installing the chip, it is best to slightly bend the pins on both sides to facilitate insertion into the corresponding socket on the base.6. Heating time: During the welding process, attention should be paid to the heating time to avoid excessive damage to the IC or PCB board. Once signs of solder melting or slight sinking of the IC are detected, heating should be stopped immediately.7. Post welding treatment: After welding is completed, wait for the PCB board to cool down, then use cleaning agent to clean and blow dry the welding points, and check for virtual soldering and short circuits. If there is any virtual soldering or short circuit phenomenon, it should be repaired in a timely manner.8. Safety precautions: When using a soldering iron or hot air gun, pay attention to safety to avoid burns or damage to other components.Following the above steps and precautions can ensure a smooth and reliable soldering process for IC chips, thereby improving the overall performance and stability of the circuit board.

03-21Knowledge

The storage and shelf life of PCB circuit boards are important steps to ensure the quality and performance of the circuit boards. Here are some key information about the storage and shelf life of PCB circuit boards:Storage conditions:1. Temperature and humidity: PCB circuit boards should be stored in an environment with a temperature range of 22 ℃± 4 ℃ and a humidity below 70% RH. For antioxidant boards, the temperature range can be relaxed to 10-28 ℃, but the humidity also needs to be controlled below 70% RH. Meanwhile, the storage location should avoid direct sunlight and preferably be stored in a dry and ventilated warehouse.2. Packaging requirements: Circuit boards should be vacuum packed or other moisture-proof measures should be taken during storage, such as using bubble wrap and moisture-proof beads. Bubble film can wrap around the side of the box, providing good moisture resistance. Meanwhile, packaged products should be classified and labeled for easy management and identification.3. Storage location: PCB circuit boards should be stored in a dry and ventilated place away from the ground, and the box must be separated from the wall to avoid moisture and temperature changes affecting them.Shelf life and precautions:1. Unopened PCB shelf life: Under the above storage conditions, the reference period for antioxidant boards is 6 months, and it is usually recommended to use them within 3 months. The reference period for other surface treatment boards is 12 months, but it is usually recommended to use them within 6 months.2. Shelf life of opened PCB: Under the same storage conditions, it is recommended to complete SMT work within one week after opening the PCB to avoid moisture or oxidation of the circuit board.3. Handling of exceeding the shelf life: If the PCB circuit board exceeds the shelf life, QA review is required. Only qualified products can be shipped, while unqualified products will be scrapped.In addition, there are some specific situations that need to be noted:• In the PCB production process, circuit boards need to be baked at 120 degrees Celsius for at least 4 hours before SMT SMT placement, which is stored in vacuum packaging for more than 3 months.• If the manufacturing date of the PCB board exceeds 2 months but the seal is not opened, it can be directly put online for use; If opened, it must be put online and used up within 5 days, and the date of opening must be indicated. If the deadline is exceeded, it needs to be baked at 120 ± 5 ℃ for a certain period of time before going online.

03-21Knowledge

There are many types of chips, and the following are some common types of chips:1. Microcontroller (MCU): This is a chip that can run programs autonomously.2. Digital Signal Processor (DSP): mainly used for processing and storing digital signals.3. Analog to Digital Converter (ADC): Used to convert analog signals into digital signals.4. Digital to Analog Converter (DAC): Used to convert digital signals into analog signals, allowing digital signals to be read by peripherals.5. Operational amplifier (OPAMP): It can amplify small electrical signals into large electrical signals.6. System on Chip (SoC): It integrates components such as microcontrollers/processors, memory, communication interfaces, and various sensors, and can achieve rich functions through simple programming.In addition, there are several common types of chips:• Memory chip: used to store digital information, including types such as memory, flash memory, EEPROM, etc. Flash memory chip is a type of chip used for data storage in digital products, mainly in two types: NAND and NOR.• DRAM chip: refers to dynamic random access memory, mainly used as internal memory in systems such as computers.• SRAM chip: static random access memory.• EPROM chip: It can program read-only memory and can be erased and reprogrammed through special UV lines.In addition, there are also types such as custom circuits (ASICs) and programmable logic devices (PLDs). Customized circuits are chips customized according to user application requirements, while programmable logic devices include a series of programmable logic chips.The above are just some common types of chips. In fact, with the development of technology, the types and functions of chips are constantly expanding and updating.

03-21Knowledge